Products

The problem

25% of homes in the United States has some damage caused by expansive soils. Expansive soils cause a greater financial loss to property owners than earthquakes, floods, hurricanes & tornadoes combined.

OUR Solution

The best protection from expansive soil is creating reliable void space when you build. Saving you the time and hassle of recovery excavation and replacement.

Use a void form you can rely on. Use Reliable Void Forms.

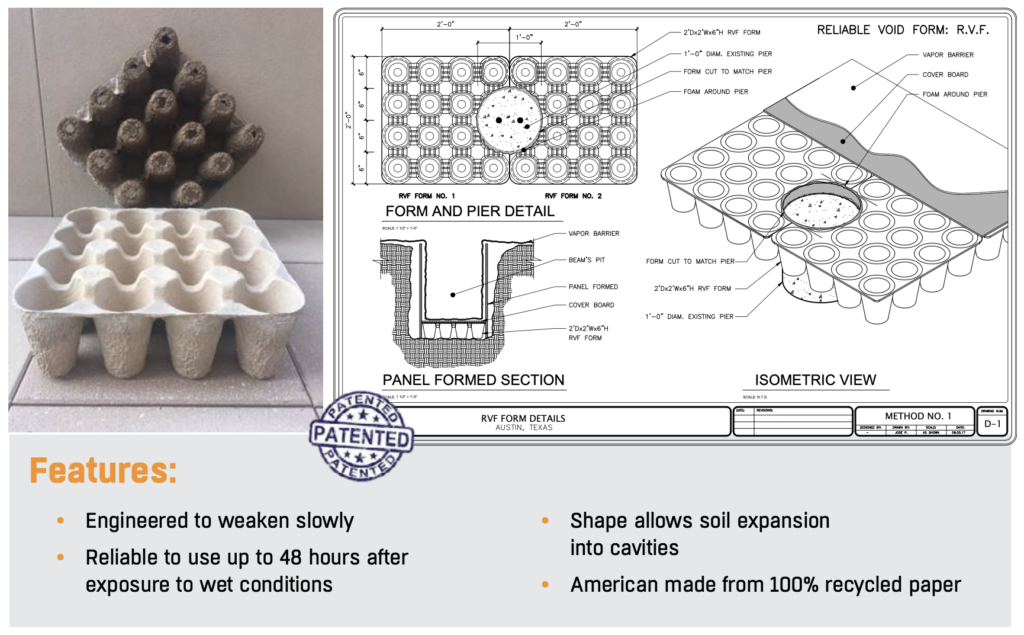

Patented cone design allows the soil to expand into the open space. With only 18% of the form in contact with the ground the soil can expand around our cones.

Void Forms

Molded Pulp Voids for under concrete structural construction

OUR Dealers

Basic Use

The unique shape and composition of the RVF gives greater strength and moisture resistance while placing the concrete over the system which consists of 1/8” hard cover and vapor barrier purchased separately. Can be placed in damp conditions.

Types

Reliable Void Forms, LLC. patented Molded Pulp Voids are used between the ground and structural concrete structures to provide a void for the expansive soil to swell into. With only 18% contact area with the ground the RVF allows the soil to expand into the open space as shown in tests done at UTSA. The RVF molded pulp void will also deteriorate over time underneath the concrete.

Composition and Materials

RVF material is a mixture of primarily blank newspaper, corrugated paper and waterresistant chemicals in a proprietary ratio. All materials are 100% recycled and are primarily post-industrial. A biocide is used to kill germs and bacteria in the pulp. Other biodegradable chemicals are added for drainage, as a retention aid, as a dry strength additive, and a sizing agent. Exact chemical additives are proprietary. Keeping it simple each void size has only one unit shaped 2’ x 2’ that can be cut or torn to fit any beam or penetration up into the concrete. RVF comes in a slab form and a beam form. The beam forms have an added moisture resistance. For shipping and storing the forms are stacked on a pallet with a pallet cover. The pallets are unloaded at the site, no need to store in a trailer or container on the job. Just keep the pallet covers on each pallet on high point of job until ready to place. No trailers to move off the job since space is limited on most job sites. No rental fees or extra freight. RVF products should be placed as recommended. Loads that exceed the manufacturer’s recommendations may cause product damage.

Installation

Prepare grade per engineer specifications. Place the RVF cones-up or cones down. Works well both ways. Break, tear or cut RVF to fit in beams and around pipes and piers or other penetrations. Cover the RVF with 1/8” hardboard and vapor barrier taped at the seams. Idea is to not allow concrete to get below the barrier to eliminate the void. See installation brochure for more detailed application instructions.

Technical Data

Research and testing data from independent engineering firm and University of Texas San Antonio is available. Contact us for more information.

PACKAGING DIMENSIONS

Warranty

Reliable Void Forms, LLC guarantees its products are free from defects in workmanship. We stand behind our products. If our forms are properly installed in accordance with our installation instructions and they fail we have product liability insurance.

Maintenance

Torn or cut pieces 6” or greater are structurally sound and can be used in the void placement. In wet conditions the forms can be used within 48 hours after exposure to moisture. If not installed when exposed to moisture allow to dry and test to see if acceptable for placement. This product can withstand some moisture. If any doubt call for representative to inspect for use.